Something I haven't done for 22 years - played with carb tuning on a Sport 1100.

We were dealers at Moto Italiano in 1995 when the Sport 1100 were released. They ran poorly at low speed, and we tried a few things to fix them that didn't really work. Looking back now I don't recall what we did, but I don't think we ever changed needles or needle jets. Probably because it went into the "too hard" basket that you often get at a dealership when you're chasing warranty issues with no support or denial from the importer/warranty issuer. It can be a very frustrating situation. Plus I didn't really have much specific Dellorto tuning experience back then, nor the info required in the form that I'm going to use here.

So when I had someone ring and ask me to tune one I was a bit reluctant. The story was that it used to run very nicely. Then someone else had played with it, and now it didn't go so well. The airbox had been removed and small pods filters fitted, and the jetting changed. It was all a bit vague and I had the feeling I should have done what I knew at least one other person had done and found an excuse not to work on it. Or just outright refused. But I have this often trouble making sense of obligation to help people, and agreed.

The original airbox got a lot of blame for the poor low speed running back in the day, but one thing it did have was the somewhat unglamorous plastic ram tubes on the back of the carbs. I don't recall how long they were, but looking at the available space and remembering what they looked like in my 1100i, I'd think they were around 150mm long. When you start looking at inlet lengths and theory and how long stuff needs to be, it generally turns out that, on motorcycle applications, you just don't have the room. The distance from the valve seat to the air entry is the length you're looking at, and for this engine running to 8,000 rpm maximum ideally it'd be in the 450mm range. More than the available.

I recalled Barry Jones of Italian Motorcycle Engineering playing with one back in the day, so I gave Baz a call to ask what he had done. He'd been involved in one fitted with FCR carbs and on that they'd moved the carbs back an extra 50mm or so to give it some more length. I thought it'd be easier to fit a ram tube of some sort, and went looking for something with a 52mm mounting ID.

I found these - Ram tubes - and figured they'd be as good a place to start as any. Not too expensive being part of the consideration when you're trying ideas that might turn out to be crap. I also needed filters, so got some of the Uni filter socks to go over them.

I had also asked Baz for any jetting recommendations. His reply of K5 and 265 made me think about how you can often overlook a simple basis. Lots of Ducati 900 bevels with PHM40 run the K4 needle and 265AB needle jet, and for Guzzi it seems to be the K5 needle and 265AB needle jet. The original setup for the Sport 1100 is K18 and 266AB. This one had K20 and 268AB. I have a spreadsheet of Dellorto needles that makes it easy to compare them in an almost visual sense, and that's where I headed before I started changing things.

Well, the first thing I changed was the float height. Set to 21mm when I started, I lifted the float level to 18mm. This is done with the carb sitting on the air filter flange and the float pivoting about and above the spindle. 18mm is pretty close to as high as they would go and still give a readable setting, whereas the older PHM were more obvious at 18mm I recall. Anyway, they were set and I moved on. I don't use float level as a tuning variable. I figure offering myself less possibilities for confusion is beneficial.

As was, the carb set up was 60/3 slide, K20 needle on the 3rd notch, 268AB needle jet, 162 main and 65 pilot. Std spec on the Sport 1100 (Euro that we got anyway) was 60/5, K18@3, 266AB, 152 and 57. The difference in the slides is the pump ramp - see my Dellorto phf / phm pump ramp profiles piece for more info there.

Comparing the needles and needle jets can be confusing, but some years ago I made a spreadsheet for just this purpose. The needle jets, like the Dellorto mains and pilots, are self explanatory - divide the number by 100 and you have the dimension in mm. A 268 needle jet is 2.68mm, a 152 main is 1.52mm and a 57 pilot is 0.57mm. On the needle jet AB denotes the physical design of the jet and what carb models it fits into. Interestingly, the Keihin FCR carbs have only one needle jet size. They offer a vast array of needles varying in root diameter (steps of 0.01mm), taper and overall length to hit the required targets.

The Dellorto needles are numbered without reason as such. All (afaik) K needles for the PHF/PHM carbs are the same overall length, being 73.5mm as I measured it. Variables are the root diameter, tip diameter, taper length and number of clip grooves. This chart shows the options. It's a bit hard to read, due to the amount of info on it. I didn't realise there were over 90 K needles - I have up to K30 on my spreadsheet.

Using the numbers I had found, I made a spreadsheet which gives needle diameter at distances from the tip in 2mm steps. It seemed about the most logical way to do it, although now that I have done some more measuring on them and found the clip grooves are 1.25mm apart using 1.25mm may have made more sense. The K5, which has 3 grooves, has the top of the clip grooves 2.75, 4.0 and 5.25mm from the top of the needle. The K20, which has 4 grooves, has the tops of the grooves 1.75, 3.0, 4.25 and 5.50mm from the top of the needle. Probably more accurate to measure from the bottom of the needle given that's how the taper is specified, but that's not important now.

The spreadsheet looks like this. This is the "sorted by #" page, and gives you the sizing info in # order.

To begin with, the important piece of info is A, the root diameter. This is the constant diameter section at the top of the needle, which controls the mixture (in conjunction with the pilot jet, mixture screw setting, slide cutaway and needle root diameter) in the first 1/4 to 1/3 of slide movement (depending on carb throat diameter, maybe even up to 1/2). Consider, realistically, how often you use more than 1/3 throttle. Unless you're getting up it for the rent, it's not as often as you might think (hope).

You can see that the K5 is 2.45mm root diameter, whereas the K18 and K20 are 2.50mm. Meaning the result of running any of these needles will depend also on the chosen needle jet, which is why you might need a 268 with the K18/20 and a 265 with the K5 sort of thing.

And so the confusion sets in.

Comparing the combinations was the next part of the spreadsheet, with a page I called "flow area". Now, the important part to remember here is that this "flow area" is a calculated number with a somewhat limited grip on reality. Reality means that there is a Boundary Layer, which refers to the fluid (be it liquid or gas) that is immediately next to a surface over which said fluid is passing. At the surface, the fluid is actually not moving, and from there the speed of the fluid increases as you move away from the surface.

In this instance of a needle in a needle jet, there are two surfaces and the important dimension that will come up later (maybe I should do it now) is the circumference of the boundary. A needle with 2.50mm diameter has a circumference of 7.85mm, and the needle jet with 2.68mm hole has a circumference of 8.42mm, giving us a total boundary layer surface width of 16.27mm which the fuel is flowing over.

Compare this to the 152 main jet, who's circumference is 4.77mm and you can see that the needle/needle jet combo has 3.4 times the surface width of the main jet. Why is this important? Well, in the comparison and calculations to come, you can calculate the flow area of the main jet and from that deduce when the main metering device (ie, biggest restriction) moves from needle in needle jet to main jet. Except that the boundary layer will impact here to some extent, and comparing the two jet systems has to allow for the impact of the boundary layer of the needle/needle jet system causing a greater restriction and thereby, in reality, giving a smaller comparative calculated flow area as compared to the main jet. ie, the needle in needle jet will remain the main metering device to a higher throttle opening (slide lift) than the numbers suggest.

So, to be clear, this is a number of some use, to be used with some notion of the fact that it's not totally realistic, in the quest for some ability to compare needle and needle jet combinations.

Compounding this is the fact that the K5 has 3 clip grooves and the K18 and K20 4 means the grooves are in different positions and therefore the relative position of the needles can vary there also. With the K5 needle and clip fitted to the second groove, there was 56.5mm of needle protruding below the slide, and 50mm of needle inside the needle jet. With a 40mm carb, and realistically 39mm or a bit more of travel from idle to WOT, this meant that the needle taper would become active around 1/3 throttle opening, and anything under that throttle opening would be controlled by (in order from closed throttle) mixture screw, pilot jet, slide cutaway and needle root diameter/needle jet diameter. Next time you're out on your Sport 1100 carby mark the throttle and take a glance to see how much you're using. 1/3 throttle is fair acceleration at any speed under quite a bit too fast for licence.

The following piece of the spreadsheet shows the needle diameters, calculated flow area and % comparison between the jetting set up. Original is the Moto Guzzi spec - K18 with 266 needle jet. 1 is the "as delivered to me": K20 and 268. 2 is my starting point: K5 and 265. 3 is my first revision: K5 and 266. 4 is my finishing point: K5 lowered 1 groove to the first and 266.

The highlighted areas are the approximate effective range of operation that will be used on the PHM40. The green area is the "non main jet" section and the yellow the "main jet" section. Apply the aforementioned disclaimers from above as required. I'd say the needle/needle jet to main jet transition is around 2/3 throttle.

You can see how much richer than std the K20 and 268 is, and the spark plugs did reflect this. The bottom line of the % comparison is the one of importance though, as that's where I ended up, and it shows how much richer then leaner my final setting of K5@1 and 266 was.

The spec for my first step was the previously fitted 60/3 slides, K5 needle with the clip in the second groove (K5@2), 265AB needle jet, 152 main jet and 60 pilot. The airbox had previously been removed and replaced with these pod filters that I generally don't like. There's no rounded transition internally into the inlet, and I don't think they flow that well either.

On the road for the first ride, it was quite flat at very low throttle and rpm - there was a real dead spot around 2,000 rpm. It really came good around 2,800 rpm and up into 3 - 3,500 rpm. On a moving with/through traffic roll on it felt a touch flat again, but rather nice anyway. Based on those two feelings, and the fact that having marked the twist grip showed that nearly any riding within any confines of traffic had the throttle less than 1/4 open, I went for the needle jet as the first change. This is the opposite of what I usually do to a 900 Ducati - SS, MHR - with PHM40, where going from a 265 to 264 needle jet cleans them up very nicely on cruise. I was after a similar minor change here, just the other way.

Ride two with K5@2 and 266 was nice. The roll on from 70 km/h (probably less than 1/8 throttle) with 1/4 - 1/3 throttle opening was lovely, and the very low speed pick up was better. Still fairly awful to ride under 2,800 rpm though, compounded by the clunky box and gearing. Then I went up from 60 to 62 on the pilot, which richened the bottom without making any real difference to how it ran under 2,800 rpm. It's a very odd feeling - if you hold the throttle constant and let it accelerate in first gear from 2,000 rpm up, the change in drive around 2,800 makes me think there's a spark advance influence here also. I don't believe it's just mixture. Going back to 57 pilots confirmed this - there was a bit of flatness around 2,500 rpm when cold, but once warm was no better or worse that with 60 or 62. ie, still crap. Idle mixture screw settings for around 5.5% CO were 57: 3, 60: 2 7/8 and 62: 2 5/8 turns out.

With the 152 mains fitted, the jetting I was running, with open pipes and pod filters, was the same as it was when the bike left the factory with the exception of the K5 needle.

Next was the trip to the dyno, to get some hard numbers and try out some inlet ideas. We ran it as it was, then removed the pods, tried some other little filters that I didn't think would be any different (they weren't), then fitted the ram tubes and Uni filters. After the WOT tests were done, we ran 1/8, 1/4, 3/8, 1/2, 5/8 and 3/4 throttle runs to check the mixture.

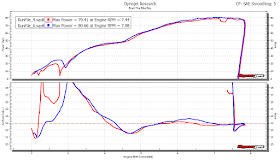

First up, pod filters versus no filters. Not sure what the dip around 7,500 is about. I'm don't know how much raising the float levels from 21 to 18mm would have changed the mixture, but I had also already gone down 10 numbers on the main jets (162 to 152) before I went to the dyno, and it was still running 12:1 or fatter. Getting rid of the filters certainly helped. The leanness at the start of the run happened for all runs over 1/4 throttle pretty much, but you know and ignore that.

(digression) One thing that did come to mind here is the shape of the air/fuel curve. Years ago I dynod a Magni, which had an over 1000cc LM4/5 engine (no idea specifically) fitted with PHM40 carbs and it had an air/fuel curve that tapered from lean to rich and made jetting a bit of a mess. With the 175 mains it came in with it would kill the engine if you held it open from 4,000 rpm - at 6,500 to 7,000 it would shut down, then come back. I figured it might be momentarily fouling the plugs. Dyno showed OMG rich - off the scale (under 10:1) by 3,500 rpm. 148 mains fixed it, but the mixture tapered in a straight line from 14:1 around 3,500 rpm to 12:1 by 7,500 rpm. My suspicion was air bleed sizing, which is not a variable in Dellortos. So I was worried that we might see a similar thing here, but also curious that the fact these carbs were made to suit this engine size and rpm range may mean they were different internally to whatever variant of PHM40 was on the Magni. Which is the inevitable incidence of "what you don't know you don't know" raising its oh so welcome head.

But the air/fuel curve is somewhat similar to what I see with the Ducati 900 motors and FCR41 carbs - a lean rise in the midrange and somewhat richer either side. The FCR39 are better (flatter curve) in that application for a 900, but gave a similar shape curve on my 750. Just another aside.

Anyway, back on track we go. Pod filters in red, no filters in blue, 152 main jet on both.

Next the trumpets went on without filters. My hope was that they would help, which they did. The dip in the curve around 4,500 has moved down a couple of hundred rpm with the extra length, but it's still there. My Sport 1100i had a similar dip, and the easiest common element to apportion blame to there is the camshaft. Not that it's a bad cam. I believe it actually came from Crane.

No filters or ram tubes in red, ram tubes without filters in blue.

The only decent air filter option I had found for the ram tubes as was were the Uni Filter socks. I did think that you could weld a flat strip to the ram tubes on the leading edge of the bell for a large K&N or the like to clamp to, but in the interests of not spending any more money than needed on parts that may not be used we went this way. Happily, they worked. No filters red, filters blue.

This gave us a WOT before/after result as below. Rather relieving and satisfying, as it turns out. The mixture leaned off to around 13.5 at 6,000 rpm, so after I got back to the factory I went up from 152 to 155 on the main, which I think helped a little with the roll on at 3,000 rpm too. Realistically, you don't ride these things by nailing it full open at 3,000 rpm, but it's nice to know it will do it and just pull.

The air/fuel traces from the part throttle runs mostly showed the same consistency in curve shape to the WOT runs, which again must be due to camshaft and maybe exhaust design. We didn't record a run under 1/8 throttle, but with it bumbling along on the dyno at 2,500 or so rpm it was even richer, under 12:1. This was with 62 pilots, and both Dave and I were sceptical of how much impact a one or two step leaner pilot would have. But, as is the case with carbs, you only have so many ways to fix an issue, so later I went to 57 and, as it was no worse, left it there. Low speed and throttle like this is controlled by pilot jet, mixture screw setting, slide cutaway and needle root diameter. Fixing it can either be a lucky guess and succeed, or many hours of trial and error.

The richness of the over 1/4 throttle runs was the reason for dropping the needles from the second to the first groove. I did that and the main and pilot jet changes after leaving the dyno (a dyno session without being covered in petrol, oh the joy), so don't have any confirmation on effects of the changes. But it felt better on the road.

Red is 1/8, blue 1/4, green 3/8, orange 1/2, dark blue 5/8 and brown 3/4. Olive is WOT as a comparison. The fact that any more than 1/2 throttle below 4,500 rpm gets you no more power is something I didn't notice beforehand, and now I'm curious if there's anything more than a change in engine noise with more throttle in that rpm range. Dyno says no, but then it is just a dyno.

The final ram tube and Uni Filter sock fitment came out as below. I cut the LH filter and spring down by 30mm to allow for the cylinder offset and to have them both ending at about the same point over the frame cross tube. I used 33-57mm clamps to hold the ram tubes to the carbs (I actually had to open the ram tubes up a little with a flap wheel to get them on the carbs, but you need to be sure they're not going to bail once out and about) and 52-76mm clamps on the socks. Given the trumpets are tapered where those clamps fit, and clamping oiled foam is like catching an eel (as good a reason as any to quote the great Mojo Nixon: "I'm slicker than two eels f***ing in a bucket of snot"), so who knows how well that'll work out long term. Undoubtedly I will be informed.

The filters come with a zip tie to hold them on, but it's a bit low rent for an external fitment.

The final result is nice above 2,800 rpm, but it's a fairly unpleasant bike to ride under that (which in second gear is 50km/h) and exaggerated by the clunky gearbox. This was made very obvious when I road tested a 1000S after servicing at the same time. The 1000S, which has similar PHM40 carbs and different, but similarly large camshaft, was a joy at low speed. It'd pull away from almost idle happily, and from memory it was running mostly std jetting (K19@3 and 268AB) with not too loud mufflers and maybe similar little mesh pods.

This prompted me to look at a couple of things, namely ignition system and gearing.

The 1000S had an original distributor and Dyna controller. As a side note (another one), when I first saw this 1000S for a big service some years ago, I checked the ignition timing and it had 20 or so degrees advance across the range. A locked distributor from a previously fitted electronic ignition (before this owner's tenure) like a Lucas Rita maybe, which didn't require the centrifugal like the Dyna does, as the Dyna simply replaces the points system to trigger to coils. Parts for these distributors are so hard to find it was easiest to buy a complete s/h distributor. A set of LM4 advance springs and away it went. Wasn't as responsive down low as before due to the lack of advance under 2,000 rpm or so, but better above it. I thought it was pretty funny, I guess someone figured 20 degrees was enough to make it work.

Anyway, it ran so much better at low speed than the Sport 1100, with more rpm at any road speed, that I thought I'd check the gearing. Turns out everything is different - primary drive, gearbox and rear drive - as below.

So the Sport 1100 gear ratios are all higher and closer together, the final drive ratio is taller, but the primary drive ratio is shorter. Overall ratios are still quite a bit taller though. I know the gearing came from the Daytona, which was theoretically geared for 270 km/h at 9,000 rpm, and the racing bikes would have gone that fast. But I still don't see the need for the road bike to have such a close ratio box.

The Daytona and Sport 1100 don't have a cush drive in the rear wheel either, so it can be quite abrupt on the on/off and the low speed baggyness only exaggerates that.

To get an idea of what can be done final drive wise, see below. I rang Mario at Thunderbikes to see what diff ratios could be swapped in, and Mario mentioned an 8/35 gearset from a V7 Sport (I think). From 8/33 to 8/35 is about 6% change, whereas 8/33 to 7/33 is 12.5%. 6% sounds pretty good. I had also thought of swapping in a 17" rear wheel from the later bikes - Daytona RS, Sport 1100i, Centauro and the V11 series all use the same wheels, 3 spoke 17" with the same disc mountings and a cush drive in the rear. Comparing the tyre sizes on a few manufacturers web sites didn't show a great deal of difference in the tyre diameters - 650mm for a 160/60ZR18 and 630mm for a 160/60ZR17 - about 3%. As the Sport 1100 and Daytona wheels are a different spoke pattern (which looks better imo), you'd need front and rear wheels to keep it matched.

Looking back at my Sport 1100i, I don't recall the gearing being something that I really thought about. But the low speed manners were much better.

The table below is calculated speeds at 8,000 rpm for each gear. This bike has had the fairing removed, so as a naked I don't think 240 km/h will be required. With the power peaking around 7,000 rpm, I don't know if it'd pull 8,000 rpm in top gear anyway.

Changing the final drive ratio, keeping in mind this is a 70,000 km old rear drive, will no doubt involve a rebuild, so as a job you'd be allowing $2,000. Going to a set of 17" wheels, with a new rear tyre, would probably end up somewhere near that too. Not a cheap gearing change. And I'd probably want a wider spread gear set in the gearbox too, just to make it nice.

The next point of thought is the ignition system. The Sport 1100 got the Marelli Digiplex system, which was also fitted to the late carb model California and Nevada as well as the Ducati 906 and 1990 900SS. The Ducati workshop manuals give advance curves, but the Guzzi manuals don't. To me, it feels like this system has a rapidly increasing advance curve coming up to 3,000 rpm, as the character of the engine just changes in a few hundred rpm. I did put some marks on the ring gear teeth so I could give it a rough check, and it didn't seem too bad, but maybe it just wants more.

More advance can make a real difference, especially to low speed response and smoothness. I tend to add quite a bit to lots of the spark advance maps when I'm playing with the fuel injected bikes just because.

It is possible to replace the Digiplex with an Ignitech to give control over the advance curve, but another concern, based on what we've seen with the Breva 1100 and 1200 models, is that more advance around 2,000 rpm or so can make them hold up on the return to idle. So maybe they found that issue back in the day with the Sport 1100. Fitting an Ignitech and setting it up, especially if you add a MAP sensor to allow extra part throttle advance via a 3D map, would run to at least $800 I'd think. So more possible fixes, but none of them cheap or guaranteed.

Fantastic article; I had a Sport new in 95, am thinking of buying my second one, and am recalling all the issues I had with getting jetting right. Your work is very timely! I've been wondering whether FCR41s are a worthwhile investment vs. optimizing the PHMs; apart from a lighter throttle pull, would FCRs improve on the dynocurve vs. optimized PHMs?

ReplyDeleteOf course, another part of me wants to simply buy a Griso 8v and be done with it...

Thanks,

Kristian

Seattle

Thanks a LOT for posting this, I have a Sport that I have about 65,000 miles on it. I have dinked around with the carbs on and off for the last few years, and “good enough “ was good enough. Unfortunately I don’t have the original airbox, just K&N pods, I have always suspected the air is so disturbed as it enters the carb was messing with the flow and preventing good atomization. I will try some Venturi tubes and see if that makes much seat of the pants difference. Unfortunately the tuning parts for Dels have gotten so expensive it is a commitment to make much change!

ReplyDelete